|

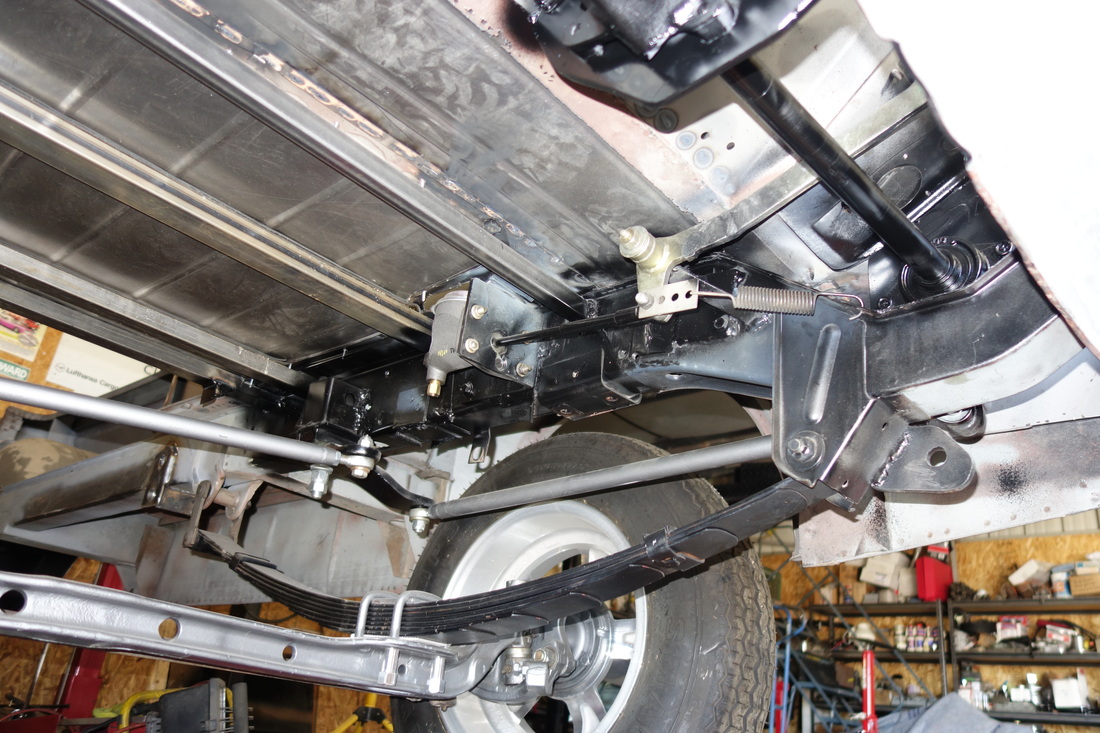

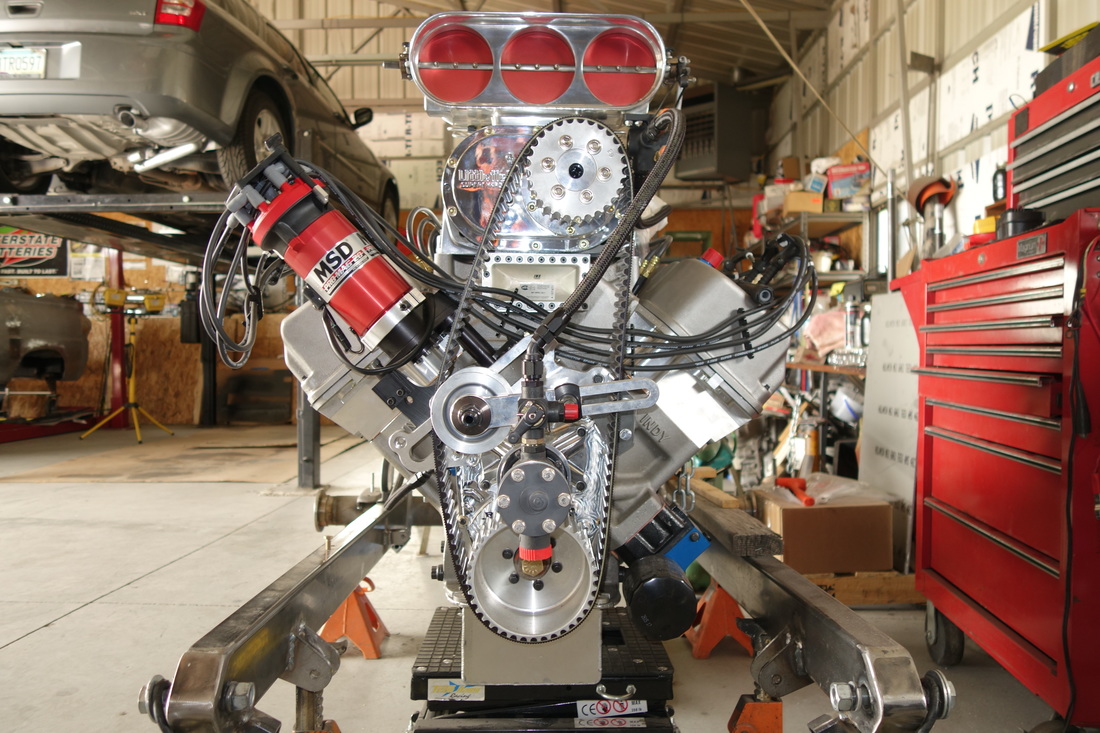

Starting with a 1965 Dodge A-100 found in the ideal climate of Arizona the unitized chassis was completely stripped in preparation for its new candy apple paint job. Note the tubbing (rear inner wheel wells) to allow 12” of rubber to fit underneath the stock rear fenders. The 5.7 (345 cubic inch) Gen III Hemi seen mounted in the truck has been replaced with an 8.6 (526 cubic inch) Gen II Hemi. See photos below of subframe

|

A heavy duty five point roll cage is installed not only for driver’s safety but to help the truck withstand tremendous horsepower and loads from being stood up on its rear wheels and its front set back down to earth.

A heavy duty five point roll cage is installed not only for driver’s safety but to help the truck withstand tremendous horsepower and loads from being stood up on its rear wheels and its front set back down to earth.

Extensive modifications to steering components were made to accommodate the center steer.

Here the entire power train is set in the subframe ready for mounts to be fabricated. Note the 12 degree angle of the engine pointing it downward. This is done to provide good oil feed when the truck is standing up and accelerating. It also keeps the weight at a lower center of gravity.

The engine and transmission alone come at a hefty price tag of $50,000. Power will be transmitted to the rear end through a Castell transfer case.

Check Back for Future Updates